Electromelting Stabilized Zirconium Oxide

*The values listed on this page are not guaranteed values but reference values.

FSD ZrO2+CaO

Applications

Ceramics materials, refractory materials, abrasives, spreading powder

Form and packaging

Yellowish white powder or grains, 25 kg paper bag

Quality property

| ZrO2+HfO2 | CaO | SiO2 | Fe2O3 | TiO2 | Stabilization rate | Particle size |

|---|---|---|---|---|---|---|

| 94.0 (Min%) |

3.5–4.3 (%) |

0.30 (Max%) |

0.40 (Max%) |

0.40 (Max%) |

70 (Min%) |

#8, #20, #40, #100, #200, #350, 350F |

FSY-8H ZrO2+Y2O3

Applications

Ceramics materials, refractory materials, spreading powder

Form and packaging

Yellowish white powder or grains, 25 kg paper bag

Quality property

| ZrO2+HfO2 | Y2O3 | SiO2 | Fe2O3 | TiO2 | Stabilization rate | Particle size |

|---|---|---|---|---|---|---|

| 89.0 (Min%) |

7.5–8.5 (%) |

0.30 (Max%) |

0.30 (Max%) |

0.40 (Max%) |

90 (Min%) |

#8, #20, #40, #100, #200, #350 |

FSD-M ZrO2+MgO

Applications

Ceramics materials, refractory materials, spreading powder

Form and packaging

Yellowish white powder or grains, 25 kg paper bag

Quality property

| ZrO2+HfO2 | MgO | CaO | SiO2 | Fe2O3 | TiO2 | Stabilization rate | Particle size |

|---|---|---|---|---|---|---|---|

| 89.0 (Min%) |

6.0 (Max%) |

0.7 (Max%) |

0.40 (Max%) |

0.40 (Max%) |

0.50 (Max%) |

70 (Min%) |

#8, #20, #40, #100, #200, #350 |

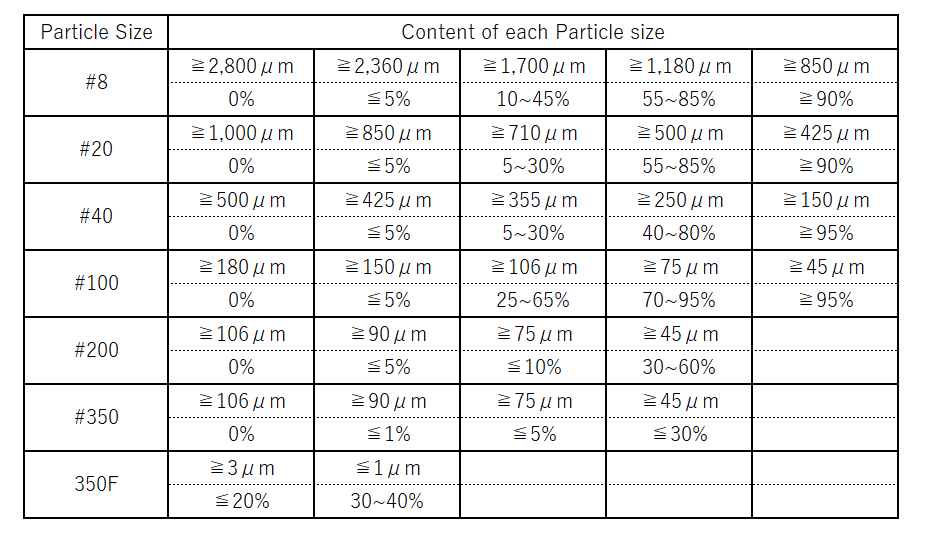

Particle Size List

*Composition modified products are also available. Please contact us for more information.

Inquiries, Request for documents

- Osaka, Tokyo

- +81-6-6231-3835